Walsworth has invested in the new DGR OCS Optical System at the Walsworth-Ripon facility.

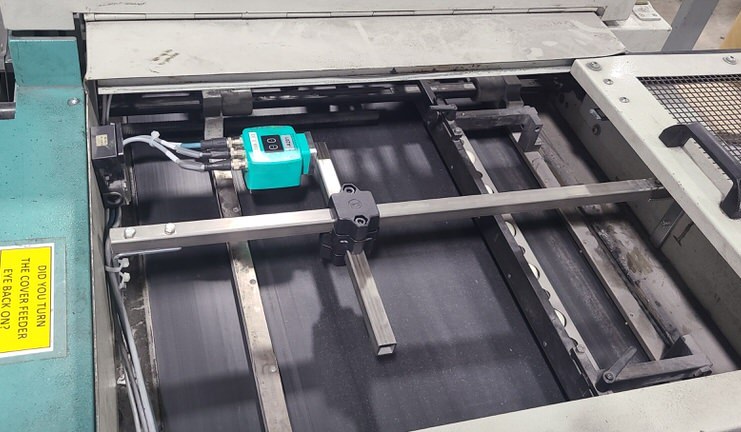

The high-resolution camera system was added to the existing Kolbus perfect binder line that served Walsworth-Ripon for many years. 32 gathering pockets and the cover feeder were upgraded with the user-friendly quality control system. For easier control, a touchscreen monitor was added at each machine.

The OCS System which reads images in high resolution came with options like barcode reading, remote service, I/O interface, reject function and cascade.

The Barcode C 128+ allows Walsworth-Ripon to check for Job ID numbers, section numbers and other information which will ensure that the complete job is produced in order.

• User friendly – The intuitive touch screen user interface combines clean layouts for best experience while limiting the menus for simple operation. All features and setting are on one page!

• Technology – High resolution camera for clear images with better performance when comparing images

• Durability – Dust proven Ethernet connectors, robust housing, and simple alignment of the camera.

• Options – Barcode reading, remote service, I/O Interface, reject function, cascade, etc.

Walsworth-Ripon and PFP have been working together for many years with an excellent relationship. Over the years this customer has trusted PFP to upgrade the existing Kolbus line with several new investments to keep up with the industry. PUR capabilities, Best for PUR conservation unit, Kolbus HD 153.P three-knife trimmer and a de-stacking unit have been added to this line in the past.

The newest addition, DGR camera system OCS will make sure Walsworth-Ripon will have a Quality Control System to match their reputation.